The company Customer Profile:

WIK (German-owned): mainly Philips, Panasonic, and other world-renowned enterprises OEM production of beauty salons and kitchen supplies, mainly to die;

Philips: international business, mainly the production of food blenders, kettles and vacuum cleaners, mold mainly exported to Austria, Brazil.

TTI (US): A large vacuum cleaner manufacturer, mainly to die;

GEW (Hong Kong): The world's second largest manufacturer toaster;

Holmes (US): The main production of air handling fans, exhaust, warming, humidification, and other varieties of machines;

AMAP (South Africa): The main production of Toyota, Volkswagen plastic interior parts;

Harman (US): The main products of multimedia speakers and accessories;

Spark Innovation (Canada): the production of stationery.

Injection mold specifications for 50-800 tons.

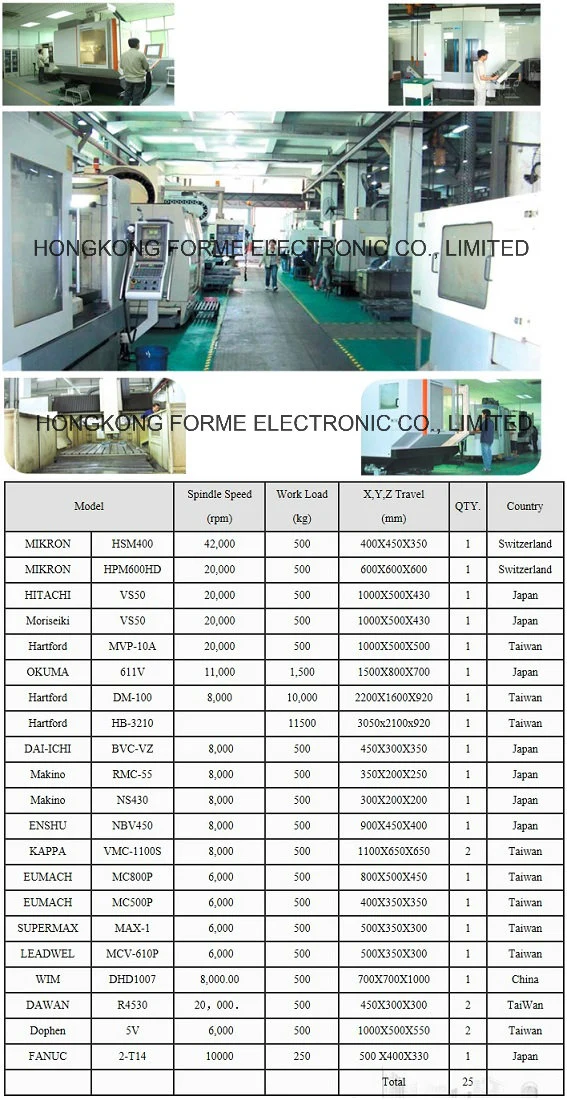

The company mainly produces equipment: CNC machine tools 10 (working range 400mm-1500mm, a high-speed machine tools) sparks seventeen units (maximum workpiece is 800mm × 1500mm, Switzerland mirror spark machine, one Taiwan), injection molding machine eight (50 tons to 550 tons), 36 electronic gongs bed, grinder 18 sets, five lathes, wire walking a Swiss, Italian CMM (coordinate detector), one Taiwan, a Taiwan projector. Now CAD / CAM system: processing software: Mastercam, Cimatron, Unigraphics; design software: Pro / E, AutoCAD, Unigraphics, Solidwork, CATIA, etc., and can be noted in customer requirements to complete the three-dimensional mold design and make injection analysis; energy acceptance DVD, Zip Driver, E-mail, FTP and other file transfer mode.